Chapter 2 Practical Considerations

Ultrasonographic instrument design

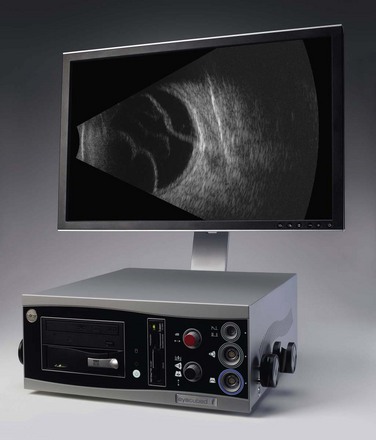

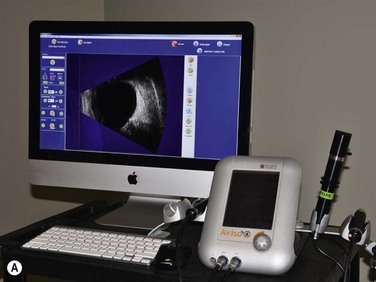

All ultrasonographic devices have four essential components: a pulse source, a transducer, a receiver, and a display screen (Figure 2.1). The ultrasound pulser produces multiple short electric pulses. The voltage pulses are sent to the transducer where a piezoelectric crystal converts electrical energy into mechanical vibrations. The vibrations generate longitudinal ultrasound waves that travel through tissues in contact with the transducer/probe. At each change in tissue density (acoustic interface) echoes are reflected back towards the transducer. Between pulses of several microseconds, the returning echoes hit the transducer and the piezoelectric crystal turns the mechanical energy into electrical energy. The resulting electrical signals are detected by the receiver, processed and displayed in real time (Chapter 1).

Axial resolution

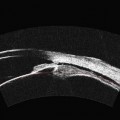

The axial resolution, or minimum distance between two echo sources, is directly related to frequency, piezoelectric crystal shape and the damping material attached to the crystal.1–3 The higher the frequency of the generated sound waves, the higher the axial resolution. For example a 10 MHz contact B-scan probe used to examine the posterior segment has an axial resolution of approximately 100 µm, while a 50 MHz ultrasound biomicroscopy probe used to examine the anterior segment has an axial resolution of approximately 37 µm (Figure 2.2) (Chapter 4). Frequencies utilized in ophthalmic ultrasonography are higher than those used in other fields of diagnostic ultrasonography, resulting in enhanced detection of small irregularities of the eye and orbit that are undetectable in structures more internally located (Chapter 1).4

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree