Chapter 2 Film/screen imaging

Introduction

In Western Europe and North America in particular the advance of digital imaging technologies would appear to be irresistible. Indeed, although film/screen technology had been argued to offer some advantages in mammography,1 digital imaging has now been shown to be at least comparable.2 Consequently, film/screen systems are rapidly being replaced by digital technologies; indeed, in the UK, film/screen systems are largely a thing of the past.

Imaging plates

The first medical radiographic image receptors were silver halide-coated glass plates, which were placed in light-tight envelopes or cassettes. Junior staff often had the task of waxing the edges of the plates to prevent the emulsion from slipping off!3

Although the value of photographic film was recognised, it was used sparingly prior to the 1920s. Once in regular use, however, the X-ray film soon proved its worth. It was quickly recognised that, unlike the early glass plates, a film could be coated on both sides. This had obvious advantages, particularly when used with intensifying screens. Because only about 1–2% of incident radiation was absorbed by the X-ray film alone, it was soon apparent that this wastefulness could be reduced by using light rather than X-rays to create the latent image on the film.4

Intensifying screens and film emulsion technology

Radiographic film

Film manufacture

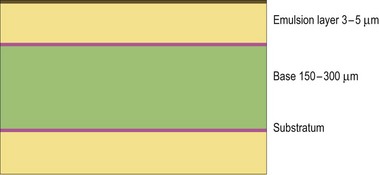

The manufacturing process is extremely stringent, as there must be no variation between batches of film. Solutions of silver nitrate (AgNO3) and potassium bromide (KBr) are added to liquid gelatine. Potassium nitrate, which is soluble, is washed away in the process.6

There are usually four stages in the preparation of the emulsion layer. It is during the latter stages that the characteristics of the film are determined. For example, the speed and contrast of the film depend on the size of the silver halide grains. A high-contrast narrow-latitude film has a narrow range of grain sizes, whereas relatively large grains will produce a film of greater speed. In the final stage various additives are introduced, such as sensitisers, colour sensitisers, hardeners, plasticisers, fungicides, antistatic agents, wetting agents and anti-foggants.5