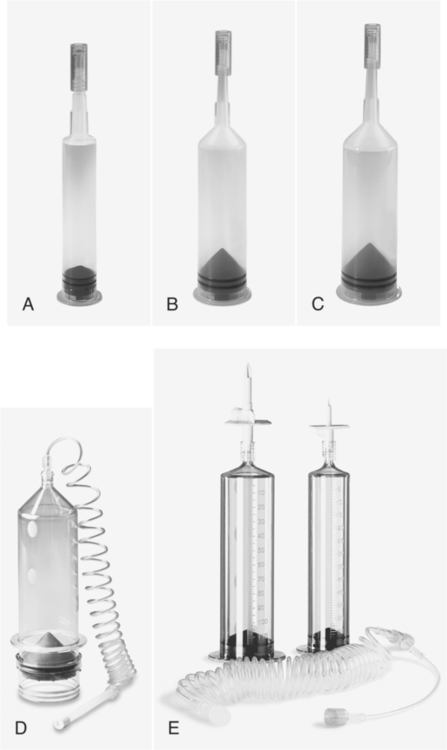

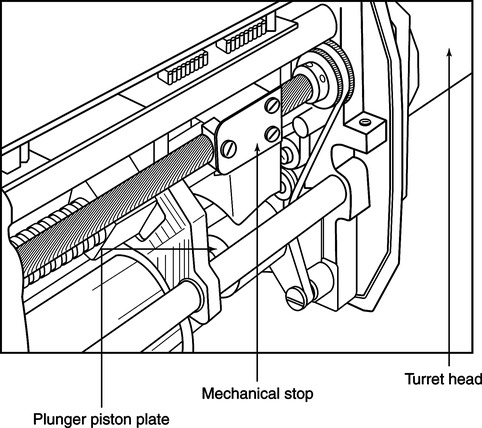

CHAPTER 3 After completing this chapter, the reader will be able to perform the following: Angiography requires the delivery of a specific amount and concentration of contrast agent to the target area. As the contrast agent enters the bloodstream, it is diluted. This dilution effect is dependent on several factors, such as the injection site, size of the vessel, and type and iodine concentration of the contrast agent. The target site determines the speed (rate of flow) of the injection. Vessel size also affects the concentration of the contrast agent. The larger the vessel, the greater the flow rate must be to maintain the proper concentration of contrast medium so that the desired anatomic features can be visualized radiographically. In some procedures, flow rates of 30 to 40 ml of contrast material per second are not uncommon.* These injections must be performed with a mechanical device in order to achieve consistency in the flow rates. The flow rate is controlled by many factors, such as the viscosity of the contrast medium, catheter length, catheter diameter, and injection pressure. The flow rate or injection speed can be increased or decreased by varying any of these parameters. Most current injectors are designed for operation as either high- or low-pressure injectors, thereby broadening their usefulness in many types of angiographic procedures. The Medrad Avanta injector (Fig. 3-1, A) is a multimodality system that can be utilized in the cardiac and angiography arena as well as for larger vessels and peripherals. The Medrad Avanta is capable of injecting contrast material in variable mode at low flow rates and low pressures, fixed mode at high flow rates and high-pressure injections, and fixed mode for saline flushing. Dedicated automatic injection systems such as the Medrad Stellant CT injection system and Spectris Solaris EP MRI injector are also available (see Fig. 3-1, B and C). These systems can be configured with options specific to each of their respective modalities. Each of the automatic injection devices has a control panel that is used to set the parameters of the injection sequence (Fig. 3-2). Depending on the unit and the optional equipment purchased, the control panel will appear more or less intricate. The injector systems are equipped with a touch screen display for ease of programming. Almost all of the units available are digitally controlled and ergonomically designed for ease of use. Some of the systems allow the control panel to be removed from the unit and taken to the control area during the procedure. The syringe must be handled with care when preparing for a procedure because any abnormality can cause failure under operating conditions. It is wise to have extra syringes available in the special procedures suite so that if syringe failure or contamination occurs, a prolonged delay can be avoided. Figure 3-3 shows some syringes in use today. Latex-free syringes are also offered by the manufacturers to reduce the possibility of allergic reactions. The injector power head is generally attached to an articulating arm that allows for a wide variety of positions during the injection. Digital displays are available on the power head indicating the protocol used and the amount of contrast available. Various configurations are available from free standing, attached to the injector module, and table or ceiling mounted power heads. Figure 3-4 illustrates some of the configurations available. The main type of high-pressure mechanism used on automatic injectors is the electromechanical system. This is simply an electric drive motor connected to a jackscrew that drives the piston into or out of the syringe. Figure 3-5 depicts a simplified version of an electromechanical high-pressure device. The high-pressure mechanisms of modern automatic injectors have several safety features built into them. The Medrad ProVis injector can prevent injections from exceeding their preset volume, flow rate, and pressure. There is also a mechanical stop that physically limits the injection volume to a preset amount. In the case of an electrical malfunction, the injection would still be limited by the device, which is not dependent upon electricity to function. Also of interest is the double-syringe assembly, which allows preloading of two syringes. When one syringe has been emptied, the plunger is retracted and the assembly is turned 180 degrees to position the second syringe with minimum resulting time loss. The Medrad Mark V ProVis provides for varying configurations of the double syringe turret assembly. The syringe assembly can be configured as 60 ml/150 ml, 150 ml/150 ml, or 200 ml/200 ml on the same turret. Table 3-1 lists the syringe sizes and their applications. The E-Z-EM CT injector also is equipped with an injector head and display that swivels independently to allow for positioning the unit on either side of the CT gantry (see Fig. 3-6). TABLE 3-1 Syringe Sizes and Their Associated Applications

Automatic Injection Devices

Identify the need for automatic injection devices

Identify the need for automatic injection devices

List the basic components of an automatic injector

List the basic components of an automatic injector

List and describe the advantages of a detachable injector head

List and describe the advantages of a detachable injector head

List and describe the advantages of dual syringe capacity

List and describe the advantages of dual syringe capacity

Define the concept of flow rate

Define the concept of flow rate

Identify the factors that affect the flow rate

Identify the factors that affect the flow rate

Explain the injectors that are used for computed tomography (CT) and magnetic resonance imaging (MRI)

Explain the injectors that are used for computed tomography (CT) and magnetic resonance imaging (MRI)

AUTOMATIC INJECTORS

Basic Components

Control Panel

Syringe

Injector Power Heads and High-Pressure Mechanism

Optional Components

Double-Syringe Assembly

Syringe Size

Application

60 ml

Carotid arteriography

Coronary arteriography ![]()

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree

Get Clinical Tree app for offline access

Get Clinical Tree app for offline access