Chapter 12 Films, cassettes, intensifying screens and processing

Radiographic film is composed of a film base with an active emulsion layer adhered using a subbing layer, with a protective super-coat.

Radiographic film is composed of a film base with an active emulsion layer adhered using a subbing layer, with a protective super-coat. Intensifying screens convert the X-rays received into light, which forms the image on the film. This reduces the exposure needed to provide a diagnostic image.

Intensifying screens convert the X-rays received into light, which forms the image on the film. This reduces the exposure needed to provide a diagnostic image. The latent image is converted into a permanent visible image through the use of developer and fixer.

The latent image is converted into a permanent visible image through the use of developer and fixer.FILMS

The production of an X-ray image depends upon the existence of materials that are unstable and, when exposed to light or electromagnetic radiation, change their nature. Halogens such as bromine or iodine are combined with silver to produce silver bromide or silver idobromide.

FILM MANUFACTURE AND SENSITIVITY

FILM CONSTRUCTION

Duplitised emulsion

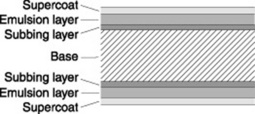

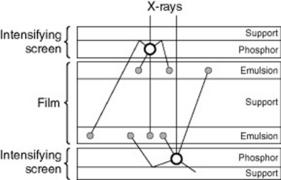

The majority of screen-type film is ‘duplitised’. This type of film has two sensitive emulsion layers – one on each side of base (Fig. 12.1). It is used for most general applications. However duplitised emulsions are also used for intra-oral dental film, although in this instance the film is exposed directly to X-radiation alone.

Film base

It is essential that the base should be:

Supercoat/anti-abrasive layer

Single-sided emulsion

Single emulsion

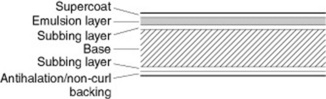

This is similar in construction to duplitised film; however, the second emulsion layer is replaced with an anti-curl/halo backing (Fig. 12.2). Curl may occur during processing as the emulsion layer absorbs processing chemicals and water and expands to a certain degree. To avoid this a layer of gelatin of identical thickness to the emulsion layer is applied to the non-emulsion aspect of the film. During processing this will expand to the same degree as the emulsion, ensuring that the dry film will lie flat. In single-sided emulsions light can be reflected at the base–air interface, back towards the sensitive emulsion layer, thus creating a halo effect (Fig. 12.3).

To minimise the halo effect a coloured dye is incorporated within the gelatin of the anti-curl backing. This acts as a colour filter and absorbs light of specific wavelengths, increasing the resolution of the image. The dye colour utilised is always the opposite colour to the exposing light source; for example yellow dye to absorb blue light. The anti-halation dye is bleached out in the fixer during the processing cycle. Processors that process large numbers of single-sided films require a higher fixer replenishment rate than those that primarily process duplitised films, as the removal of anti-halation dye utilises more fixer energy.

Advantages of using duplitised emulsions

Image resolution and use of films

Irradiation

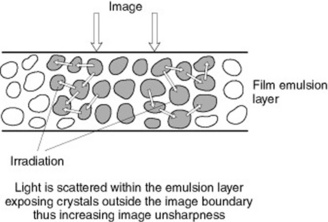

This is the sideways scattering of light within the emulsion layer as a consequence of light striking the silver halide crystals (Fig. 12.4). This is a cause of image unsharpness, as the scattered light does not contribute to the primary image.

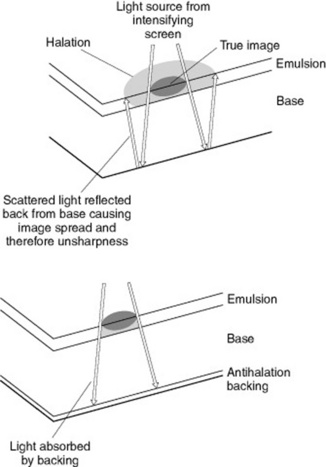

Halation

Halation occurs when an image is formed by light and some of this incident energy passes through the emulsion to the base. On reaching the base–air interface this light either passes out of the film or is reflected back towards the emulsion layer where it creates unsharpness by interacting with silver halide crystals.

Crossover

Crossover creates an increase in image unsharpness because light that is not completely absorbed in the emulsion layer nearest to source of light passes through the film base and subsequently interacts with silver halide crystals in the opposite emulsion layer, creating a wider and thus less sharp image (Fig. 12.5).

CASSETTES

In radiographic terms a cassette normally houses and provides a physically safe and light-tight environment for both the film and the intensifying screens in which the processes associated with fluorescence and the formation of the latent image can occur (Fig. 12.6). Cassettes are available in various sizes and with detailed differences between specific manufactures.

CONSTRUCTION

The criteria for an effective cassette include: