X-Ray Production, Tubes, and Generators

6.0 INTRODUCTION

This chapter describes the x-ray production process, characteristics of the x-ray beam, x-ray tube design x-ray generator components, and factors that affect exposure and exposure rate.

6.1 PRODUCTION OF X-RAYS

1. Bremsstrahlung spectrum

a. Conversion of kinetic energy of electrons into electromagnetic radiation (x-rays).

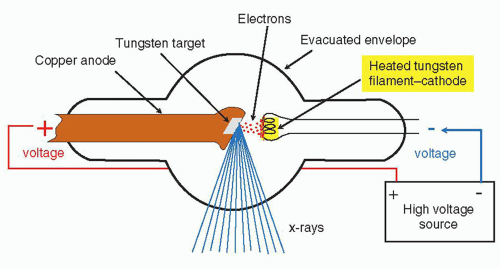

b. An environment and requirements to produce x-rays are shown in Figure 6-1.

c. Voltage applied to the cathode and anode accelerates electrons to a kinetic energy = voltage.

d. Electrons interact with other electrons to produce heat; electrons that interact with the nucleus of the tungsten target are decelerated through coulombic interactions as illustrated in Figure 6-2.

e. X-ray energies produced have a distribution described by the bremsstrahlung spectrum (Fig. 6-3).

f. Efficiency of x-ray production relative to heat production is typically less than 1%.

▪ FIGURE 6-1 Configuration of a simple x-ray tube with essential components listed. Electrons are generated by filament heating and thermionic emission. An external voltage accelerates the electrons to a kinetic energy equal to the potential difference (voltage) applied between the cathode and anode. Most electrons collide with target electrons and produce heat. A small fraction interact with the nucleus as shown in Figure 6-2.

2. Characteristic X-rays

a. Incident electrons can interact with inner orbital electrons of the target atom.

b. Requires incident electron kinetic energy greater than binding energy of the electron in the atomic orbital.

c. Vacant shell via ejected electron from the target atom is immediately filled with electrons of lower binding energy, generating a “characteristic x-ray” of discrete energy equal to energy difference.

d. Electron binding energies of pertinent target materials are listed in Table 6-1.

e. Characteristic x-ray formation is illustrated in Figure 6-4 and resultant spectrum in Figure 6-5.

f. KA and KB characteristic x-ray energies result from adjacent shell and nonadjacent shell transitions.

TABLE 6-1 ELECTRON BINDING ENERGIES (keV) OF COMMON X-RAY TUBE TARGET MATERIALS | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

6.2 X-RAY TUBES

1. Cathode

a. The negative electrode comprised of electron emitters (filaments) and focusing cup; filament length provides small and large focal spot selections (Fig. 6-8).

b. Filament circuit activates filament to release electrons due to thermionic emission. A flow of electrons occurs when a voltage is applied; note difference of filament and tube current (Fig. 6-9).

c. Focusing cup shapes the electron distribution accelerated toward the anode; biased cups (more negative) can produce smaller distributions; grid biased focusing cups can stop flow (Fig. 6-10).

2. Anode

a. The target electrode maintained at positive potential difference with respect to the cathode.

b. Tungsten (W), Z = 74, has a high melting point—used for most diagnostic systems.

c. Molybdenum (Mo), Z = 42, and rhodium (Rh), Z = 45, produce characteristic x-rays beneficial for mammography imaging (see Chapter 8).

3. Anode configurations

a. Stationary tungsten target embedded in a copper block (copper efficiently conducts heat) (Fig. 6-11)

(i) Used in low-power applications such as dental x-ray and handheld fluoro units

b. Rotating anode—higher heat-loading capability achieved by spreading out area of power deposition

(i) Requires induction motor (stator-rotor design) to rotate at 3,000 to 10,000 rpm (Fig. 6-12)

4. Anode angle, field coverage, focal spot size

a. Anode angle: surface of the focal track to the perpendicular of the anode-cathode axis (Fig. 6-13).

b. Actual focal area length is foreshortened when projected down central axis according to the line focus principle: Effective focal length = Actual focal length × sin θ, where θ is the anode angle.

c. Focal spot effective size: width (determined by the focusing cup) × length (filament length).

d. Field coverage: dependent on anode angle and source to image distance (Fig. 6-14).

e. Effective focal spot varies in size along cathode-anode direction of the projection beam (Fig. 6-15).

f. Measurement of focal spot size can be achieved by a pinhole camera, slit camera, star pattern, or resolution bar patterns (see Figs. 6-17, 6-18, and 6-19 in the textbook).

g. Nominal focal spot sizes are specified by the International Electrotechnical Commission (see Table 6-3 in the textbook).

5. Heel effect

a. Reduction in beam fluence on the anode side of the projected field caused by anode self-attenuation.

b. Heel effect is more prominent at short source-image distances (Fig. 6-16).

c. Orientation of the x-ray tube is important for equalizing transmitted x-ray fluence (Fig. 6-17).

6. Off-focal radiation

a. Incident electrons elastically rebound and impact the anode at areas outside of the focal spot.

b. Causes extra radiation dose, background signal, and geometric blurring (see textbook Fig. 6-22).

c. This effect is reduced with a grounded anode and hooded structure next to the anode focal area.

7. X-ray tube insert

a. Evacuated glass or metal enclosure containing the x-ray tube structures (see Figs. 6-6 and 6-7 above).

b. “Getter” circuit is used for trapping released outgassing of internal x-ray tube components.

c. Tube port made of beryllium (Be) is necessary for x-ray tubes employed for mammography.

8. X-ray tube housing

a. Provides mechanical, electrical, thermal, and radiation protection.

b. “Leakage x-rays” are reduced by lead shielding in the housing (typically 2 mm or more thick) to radiation levels no greater than 0.88 mGy air kerma (100 mR) per hour at 1 m from focal spot when using the highest kV at the highest continuous tube current (typically 125 to 150 kV and 3 to 5 mA).

c. Heat exchangers are used with high-power x-ray tubes by circulating the housing transformer oil.

9. X-ray tube filtration

a. Added metal filters (typically aluminum or copper sheets) placed near the tube port in the beam.

b. Tube total filtration includes inherent filtration of the insert material plus the added filters.

c. Compensation filters are used to modify the incident spatial fluence of the x-ray beam.

d. Wedge, trough, and bow-tie filters (the latter typically used for CT tubes) are used.

e. Filters chiefly modify the x-ray spectrum to selectively remove low-energy x-ray photons and lower radiation dose to the patient.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree